Contents

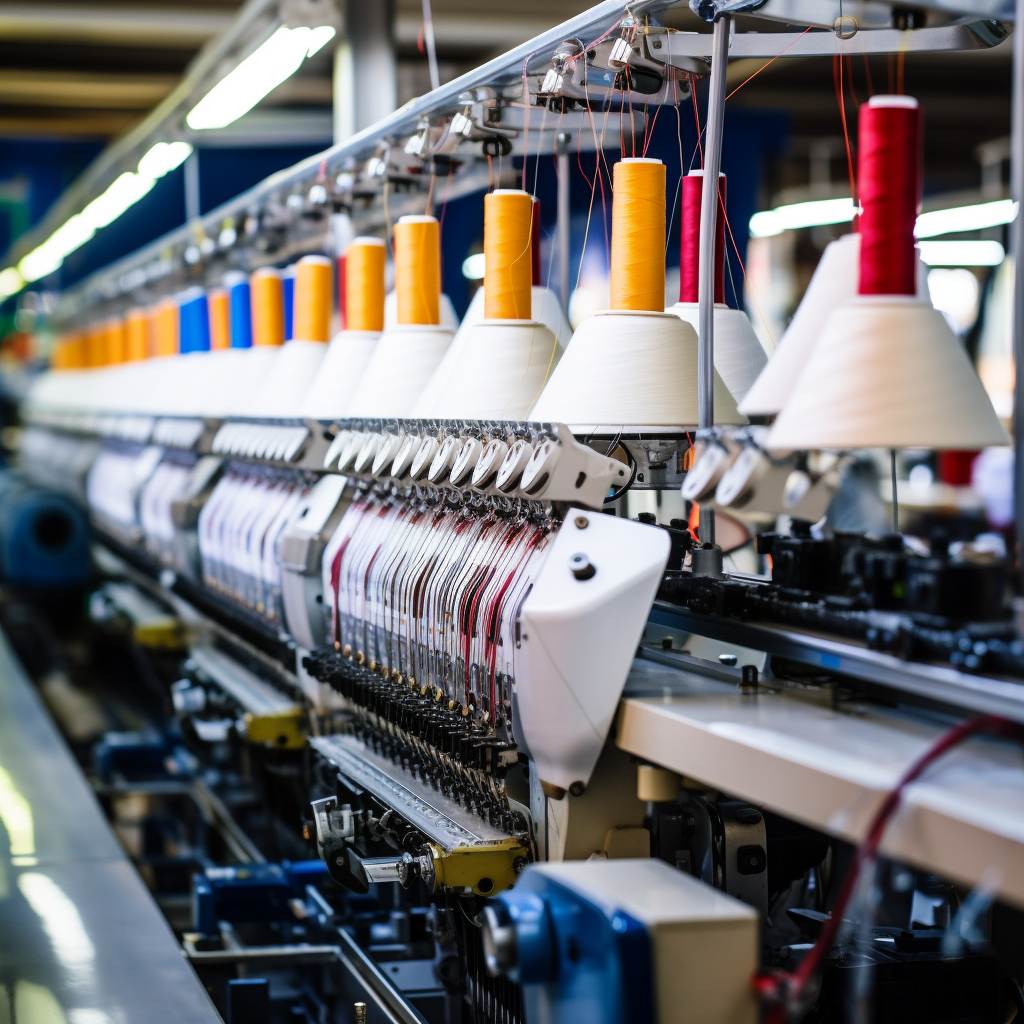

The backbone of any garment factory lies in its machinery. The right selection and use of machines can drastically transform the production rate and quality of the finished products. Whether it’s the meticulous detail from an embroidery machine or the sturdy stitching from a sewing machine, each plays a significant role in creating the final product.

In a typical garment factory, a multitude of machines are at work, each serving a specific purpose. From sewing machines that piece together the fabrics, cutting machines that carve out the patterns, to the finishing machines giving the final touches, it’s a well-coordinated dance of technology.

In this article, we will delve into the types of machines required in a garment factory, examining their functionalities and importance. Our aim is to provide a comprehensive guide to both individuals and businesses interested in understanding the nuts and bolts of garment production machinery.

Whether you’re a seasoned manufacturer looking to optimize your production line, or a newbie looking to break into the industry, this detailed exploration of machinery in a garment factory should serve as a useful resource.

Stay tuned as we unravel the world of garment manufacturing machines, their integral roles, and how they contribute to the entire garment production process.

1: Sewing Machines

One of the essential tools in a garment factory is the sewing machine. This is the workhorse that stitches the fabric pieces together, giving them the form of a garment. There are various types of sewing machines used, each designed for a specific purpose and type of stitch. Let’s take a closer look.

- Lockstitch Sewing Machine: These are the most common types used in garment factories. They produce a lockstitch, the most secure stitch, using two threads, one on the top and one on the bottom.

- Overlock Sewing Machine: An overlock machine, also known as a serger, is used for seaming or overlocking the edges of the fabric. It can also trim the edges as it sews.

- Flatlock Sewing Machine: These machines are used for hemming, seaming, or decorative purposes. They produce a flat, lapped seam that’s comfortable against the skin, which is particularly useful in sportswear.

- Buttonhole and Button Sewing Machine: These machines, as the name suggests, are used to create buttonholes and sew buttons onto the garments.

- Double Needle Sewing Machine: Double needle machines are often used for decorative stitching or parallel rows of stitching, offering a professional finish.

- Blind Stitch Sewing Machine: These machines create stitches that are invisible or nearly invisible on the right side of the garment, often used for hems.

Table 1: Types of Sewing Machines and Their Uses

| Type of Sewing Machine | Use |

|---|---|

| Lockstitch Sewing Machine | Produces the most secure stitch using two threads |

| Overlock Sewing Machine | Used for seaming or overlocking the edges of the fabric |

| Flatlock Sewing Machine | Used for hemming, seaming, or decorative purposes |

| Buttonhole and Button Sewing Machine | Used to create buttonholes and sew buttons onto the garments |

| Double Needle Sewing Machine | Used for decorative stitching or parallel rows of stitching |

| Blind Stitch Sewing Machine | Creates stitches that are invisible or nearly invisible on the right side of the garment |

From sewing simple seams to adding elaborate decorative touches, the sewing machine is an indispensable part of the garment factory. The versatility and efficiency of this tool are what make it a cornerstone in the garment manufacturing process.

2: Cutting Machines

Cutting machines play a critical role in garment manufacturing. These machines ensure precision in cutting fabric into the desired patterns and shapes, a vital step before sewing can commence. Let’s explore some of the main types used in the industry.

- Straight Knife Cutting Machine: As the most common cutting machine in garment factories, it consists of a base plate, an upright standard carrying the motor and driving mechanism, and a straight blade.

- Round Knife Cutting Machine: With its circular blade, this machine is ideal for cutting stacks of fabric and is widely used for its speed and efficiency.

- Band Knife Cutting Machine: It’s equipped with a continuous band knife and is perfect for intricate cuts and curves, offering a high degree of precision.

- Die Cutting Machine: Die cutting machines employ pre-shaped molds, or dies, to cut fabric into specific shapes, making it suitable for large-scale production of identical patterns.

- Laser Cutting Machine: These use laser technology for precision cutting and are typically used for intricate patterns and designs.

Table 2: Types of Cutting Machines and Their Uses

| Type of Cutting Machine | Use |

|---|---|

| Straight Knife Cutting Machine | Used for cutting stacks of fabric with straight lines |

| Round Knife Cutting Machine | Ideal for cutting stacks of fabric quickly and efficiently |

| Band Knife Cutting Machine | Used for intricate cuts and curves with a high degree of precision |

| Die Cutting Machine | Used for large-scale production of identical patterns |

| Laser Cutting Machine | Used for intricate patterns and designs with precision cutting |

Each of these cutting machines plays a unique role in the garment factory. Their precision, speed, and efficiency are critical to maintaining the smooth flow of production and achieving the desired quality of garments.

3: Finishing Machines

The final steps of garment production involve the finishing process, which is integral to the look, feel, and quality of the finished product. This is where finishing machines come in. They lend the final touches to the garments, making them ready for the market.

- Pressing or Ironing Machines: These machines are used to press garments and eliminate any wrinkles or creases. They come in various types, such as steam irons, gravity feed irons, and boiler irons, each serving a specific purpose.

- Fusing Machines: Fusing machines are used to attach interfacing, linings, or decorative details to garments. They use heat and pressure to bond materials together, ensuring a clean, finished look.

- Dryers: After the washing process, garments are dried in industrial dryers. These machines use heat and air movement to efficiently dry large quantities of garments.

Table 3: Types of Finishing Machines and Their Uses

| Type of Finishing Machine | Use |

|---|---|

| Pressing or Ironing Machines | Used to press garments and eliminate any wrinkles or creases |

| Fusing Machines | Used to attach interfacing, linings, or decorative details to garments |

| Dryers | Used to dry garments after the washing process |

Finishing machines help ensure that the garment meets the desired aesthetic and quality standards. They put the ‘finishing touches’ on the garment, ensuring it is ready for sale.

4: Embroidery Machines

Embroidery machines bring decorative and branding elements to life on the fabric. With these machines, garment manufacturers can add detailed and intricate designs that greatly enhance the aesthetics and value of their products.

- Single Head, Single Needle Embroidery Machine: As the simplest form of an embroidery machine, it’s perfect for small-scale production, bespoke pieces, and intricate designs.

- Single Head, Multi-Needle Embroidery Machine: This machine is capable of producing multi-color designs without the need to change threads, which makes it ideal for medium-scale production.

- Multi-Head, Multi-Needle Embroidery Machine: These machines are designed for large-scale production. With multiple heads and needles, they can produce multiple pieces simultaneously.

Table 4: Types of Embroidery Machines and Their Uses

| Type of Embroidery Machine | Use |

|---|---|

| Single Head, Single Needle Embroidery Machine | Perfect for small-scale production, bespoke pieces, and intricate designs |

| Single Head, Multi-Needle Embroidery Machine | Ideal for medium-scale production with multi-color designs |

| Multi-Head, Multi-Needle Embroidery Machine | Designed for large-scale production and capable of producing multiple pieces simultaneously |

These machines not only add beauty to the garments but also serve functional purposes such as branding or labeling.

5: Knitting Machines

Knitting machines are crucial in the production of knitwear, such as sweaters, cardigans, and socks. Unlike sewing machines that stitch pieces of fabric together, knitting machines create fabric by interlocking loops of yarn. Let’s delve into the main types used in garment factories.

- Weft Knitting Machines: This type of knitting machine creates fabric in a circular or flat manner. It’s used to produce fabrics for clothing like t-shirts and sweaters.

- Warp Knitting Machines: These machines are predominantly used for the production of textiles like lace or mesh. They work at high speeds and are generally used for large scale production.

Table 5: Types of Knitting Machines and Their Uses

| Type of Knitting Machine | Use |

|---|---|

| Weft Knitting Machines | Used for making fabric for clothing like t-shirts and sweaters |

| Warp Knitting Machines | Used for the production of textiles like lace or mesh, ideal for large scale production |

These machines, though used less frequently than sewing machines, are vital in a garment factory that produces knitted garments.

6: Fusing and Pleating Machines

Fusing and pleating machines play vital roles in garment manufacturing, particularly in the production of formal wear and decorative pieces. These machines offer unique functionalities that can significantly enhance the value of a garment.

- Fusing Machines: Fusing machines are essential for attaching interfacing to a garment piece to provide shape and structure. These machines use a combination of heat and pressure to bond the interfacing to the fabric.

- Pleating Machines: Pleating machines are used to create pleats, a type of fold formed by doubling fabric back upon itself and securing it in place. They’re commonly used in the production of skirts, dresses, and other garments where decorative or structural folds are required.

Table 6: Fusing and Pleating Machines and Their Uses

| Type of Machine | Use |

|---|---|

| Fusing Machines | Used for attaching interfacing to provide shape and structure to the garment |

| Pleating Machines | Used for creating decorative or structural folds in the fabric |

Fusing and pleating machines allow manufacturers to add intricate details and structure to garments, further enhancing their aesthetic appeal and value.

7: Special Machines

Some machines in a garment factory serve very specific purposes. Although their use may be limited to certain types of garments or designs, their role is integral to the final product’s look and quality. Let’s look at some of these special machines.

- Buttonhole Machines: As the name suggests, these machines are designed to create buttonholes in garments. They ensure the buttonholes are uniform and professionally finished.

- Button Stitch Machines: After the buttonholes are made, the button stitch machines are used to securely attach buttons to the garments.

- Bartack Machines: These machines are used to provide reinforcement to areas of the garment that may be subject to stress or strain, such as pocket openings and belt loops.

- Pattern Sewing Machines: These machines are programmed to create specific patterns or decorative stitching on garments, allowing for high precision and consistency.

Table 7: Special Machines and Their Uses

| Type of Special Machine | Use |

|---|---|

| Buttonhole Machines | Creates uniform and professionally finished buttonholes |

| Button Stitch Machines | Used to securely attach buttons to the garments |

| Bartack Machines | Provides reinforcement to areas of the garment subject to stress or strain |

| Pattern Sewing Machines | Programmed to create specific patterns or decorative stitching |

These machines, though used less frequently than the primary machines, are key to achieving the finishing touches that distinguish a well-crafted garment.

8: Supporting Machines

Beyond the primary production machines, a garment factory requires several supporting machines. These machines may not directly contribute to garment production but play a crucial role in maintaining the operational efficiency of the factory. Here are some of these key supporting machines.

- Boiler Machines: These machines are used to generate steam that is often required in pressing and ironing machines. They ensure a steady supply of steam for smooth operation.

- Air Compressor Machines: Air compressor machines are vital in a garment factory as they supply compressed air to operate various pneumatic tools and machines.

- Generator Sets: Given the high power requirements of a garment factory, having a backup power source like a generator set is crucial to ensure uninterrupted production.

Table 8: Supporting Machines and Their Uses

| Type of Supporting Machine | Use |

|---|---|

| Boiler Machines | Generate steam for pressing and ironing machines |

| Air Compressor Machines | Supply compressed air to operate various pneumatic tools and machines |

| Generator Sets | Provide backup power source for uninterrupted production |

These supporting machines ensure a smooth and efficient operation, helping to maintain the productivity of the factory and minimize downtime.

With this, we have covered the primary types of machines needed for a garment factory. It’s clear that from cutting to finishing, and even in supporting roles, machinery plays a crucial part in garment manufacturing. Whether you’re planning to set up a garment factory or simply looking to improve your existing operations, understanding the function and importance of these machines is vital.

Conclusion

Machinery forms the backbone of any garment manufacturing operation. The right selection and efficient use of these machines determine not only the productivity of the factory but also the quality of the garments produced.

The process begins with cutting machines that shape fabrics into patterns. Next, sewing machines join these cut pieces to form the structure of the garment. Embroidery machines are then used for embellishing the garments, followed by the use of fusing machines and pleating machines for shaping and decorating. Finally, the garments go through finishing machines for pressing, drying, and quality checking.

In addition to these, special machines like buttonhole machines, button stitch machines, bartack machines, and pattern sewing machines add unique features and reinforcements to the garments. Lastly, supporting machines like boiler machines, air compressor machines, and generator sets ensure the smooth functioning of all these primary machines.

Table 9: Summary of Machines Used in a Garment Factory

| Type of Machine | Key Use |

|---|---|

| Cutting Machines | Shape fabrics into patterns |

| Sewing Machines | Stitch fabric pieces together |

| Embroidery Machines | Add decorative designs |

| Fusing and Pleating Machines | Shape and decorate garments |

| Finishing Machines | Final quality check and finishing touches |

| Special Machines | Add unique features and reinforcements |

| Supporting Machines | Ensure smooth functioning of primary machines |

In essence, understanding the role and functionality of each type of machine is crucial in running a successful garment factory. It not only facilitates efficient production but also allows for better quality control and cost management.

With careful planning and the right mix of machines, a garment factory can ensure the production of high-quality garments that meet market demands, thus leading to success in the competitive world of fashion.

FAQs

- What is the most commonly used machine in a garment factory? The most commonly used machine in a garment factory is the sewing machine. It is the primary tool used to stitch fabric pieces together to form garments.

- What is the role of cutting machines in a garment factory? Cutting machines are used to cut fabrics into specific shapes and patterns before sewing. They ensure precision in cutting, which is crucial for the quality of the final garment.

- What are fusing machines used for? Fusing machines are used to attach interfacing, linings, or decorative details to garments using heat and pressure. They help provide structure and shape to the garments.

- What are the supporting machines in a garment factory? Supporting machines, like boiler machines, air compressor machines, and generator sets, help ensure the smooth operation of primary machines. They provide necessary utilities like steam and compressed air, and backup power.

- Why are special machines needed in a garment factory? Special machines, like buttonhole machines and bartack machines, are used to add unique features and reinforcements to garments. They help enhance the garment’s aesthetic appeal and durability.